Manufacturers and exporters of 3D hot induction pipe bend.

Our Manufacturing facility produces 3D pipe bends and 3d elbows in the required material grades of Carbon steel, Stainless steel, and chrome-moly alloy steel.

Aditya Steel Engg. Co. manufactures ASTM A234 WPB, 3D long and short radius steel bends, ASTM A403 Stainless Steel Pipe bends, ASME B16.9 Butt Welding bends, ASME B16.11 Forged Steel Bends, MSS SP-75 WPHY Fittings, and ASTM A860 grade WPHY hot induction bends.

Manufacturer of 3D hot induction pipe bend.

Many various applications, including shipbuilding, power plants, water treatment facilities, refineries, and the petrochemical industry, use this long radius bend. According to the requirements of the clients, these are available in a variety of sizes, classes, types, and schedules. JF Engineering is one of the leading producers of high-quality ANSI/ASME Long Radius 3D Bend products. We promise to deliver high-quality goods to the market. In these times of engagement, we provide the highest calibre products at the most competitive prices.

Manufacturer and exporters of ANSI B16.29 Long Radius 3D Bend, manufacturer of ASME B16.28 ASTM A860 WPHY 42, 52, 60, 65, 70 Long Radius 3D Bend, manufacturer of API 5L X52, X56, X60, X65, X70 Long Radius 3D bend, ASTM A234 WPB long Radius 3D Bend, SCH 80 long Radius 3D Bend in in India.

We are enthusiastic about producing high quality pipe 3D bends for permanent welds at Aditya Steel Engineering Co. We have been a trustworthy partner when it comes to creating pipe induction bends for the authorized market for more than 20 years since we comprehended the needs and uses of our clients. Worldwide, we are present where our clients are.

3D Pipe Bends Description.

O.D. : 38.0 mm – 508.0 mm.

A234 WPB U Bend Size : Seamless 1/2 inch to 20 inch; Welded / ERW : 6 inch to 36 inch.

Available Radius : 3D Bends Short and Long radius.

Bends Radii : 75 / 100 / 150 / 250 / 300 / 500 / 800 / 1,000 / 1,200 / 1,500 mm.

Types : Welded, Seamless, ERW, Fabricated

Specifications

| 3D BEND Standards: | ANSI – B 16.9 ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’ API 590-605 ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings” ASME B16.25 – ‘Buttwelding Ends’ ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| 3D BEND Schedule: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| 3D BEND Materials: | Stainless Steel : Grade: ASME / ASTM SA 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70, A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91, A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 304H, 316H, 316/316L, 321, 330, 347, 309/S, 310/S, 317/L, 333, 410/S, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| 3D BEND Type: | Butt Weld (BW), Dish End |

| 3D BEND Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313, ASME B16.9, ANSI B16.28, ANSI B16.25 |

Surface Finish on Steel tube mandrel bends

- ❖ Hairline

- ❖ Galvanized

- ❖ Shot blasting

- ❖ Anti Corrosive

- ❖ Black Phosphating

Manufacturing Standard for 3D BEND

- ➤ EN: EN10253-1, EN10253-2

- ➤ ASME: ANSI B16.9, ANSI B16.28, MSS-SP-43

- ➤ DIN: DIN2617, DIN2605, DIN2616, DIN2615, DIN28011

Manufacturer and Suppliers of 3D Hot Induction bend

Manufacturer of ASME / ASTM SA 234 WPB 3d hot induction bend

Manufacturer of WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70 3d hot induction bend

Manufacturer of A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 3d hot induction bend

Manufacturer of A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 304H, 316H, 316/316L, 321, 330, 347, 309/S, 310/S, 317/L, 333, 410/S, DIN 1.4301 3d hot induction bend

Manufacturer of DIN1.4306, DIN 1.4401, DIN 1.4404 3d hot induction bend

ASME/ASTM certified 3d hot induction bend manufacturer in India, Dubai, Indonesia, Europe, Japan, Korea Etc.

IBR Approved or certified 3d hot induction bend manufacturer in Pune, Mumbai, Benglore, Chennai, Maharashtra, India.

EIL Approved or certified 3d hot induction bend manufacturer in Pune, Mumbai, Benglore, Chennai, Maharashtra, India.

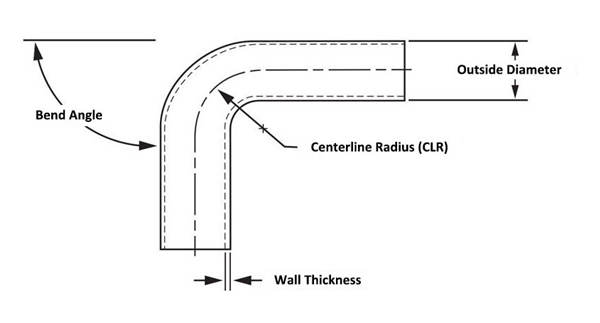

3D BEND Bending Radius of Bend and Elbow

As we talked above,

Steel pipe bend radius: Above 2 times of D, so there are 2D, 2.5D, 3D, 5D, 6D, 7D or 8D pipe bend.

Steel pipe elbow radius: R=1D or R=1.5D or 2D. Below 1.5D is short radius elbow, and more than 1.5D but not over 2D is long radius elbow.

R is radius of curvature; D is (elbow or bend) pipe diameter.

As above picture CLR could be in 1D, 1.5D, 2D, 3D, 5D, 7D, 10D. etc.

Different of manufacturing processes

Bend: Could be bend directly from a finished pipe with cold bending processes, to different degrees.

Elbow: Shall be made according by standard manufacture procedures, with hot finishing or hot bending, to a certain degree, 45°, 90° or 180°.

Cost different

So by the help of simple production process with standard 1.5D or 1D, steel pipe elbow cost is lower than bend. Pipe bend is mostly required with customized radius or degrees so the processes is more complicated than elbow and cost is higher.

Different applications scope

Bend: Compatible with slower liquid and lower pressure.

Elbow: Compatible with high pressure and rapid liquid.

Sometimes elbows must be used in narrow sections, because the radius of curvature of the elbow is small, generally 2D, but the pipe bend could be up to 40D.

Our All Products

BUTT WELD FITTINGS, ELBOW (45, 90, 180 DEG.), ECC./CON. REDUCERS, EQUAL TEE & CROSS, UNEQUAL TEE & CROSS UNEQUAL , CROSS TEE, Two Half Weld Joint Fittings, Two Half weld joint equal tee / Unequal Tee, Two Half Weld Joint Elbow, SOCKET WELD FITTINGS, REDUCER INSERT (3000PSI, 6000PSI), FORGED STEEL OUTLET FITTINGS, PLUGS AND BUSHINGS , Socket Weld and Screwed Fittings, FLANGES & FORGING, CLASS 300 FLANGES, CLASS 600 FLANGES, CLASS 1500 FLANGES, CLASS 2500 FLANGE, ASTM A105 Flanges, ASTM A350 Lf2 Flanges, SPECIAL FORGED FITTINGS , Hot Pipe induction Bend Manufacturers, SPECIAL RADIOS BEND, Mitered Elbow / Bend, FERRULES, TUBE INSERTS, Inconel Alloy 601 Ferrules / Tube Inserts, Inconel Alloy 602CA Ferrule / Tube Inserts, Virgin PTFE Tube Inserts OR Virgin PTFE Ferrules , Inconel Alloy 693 Ferrule or Tube Inserts, CU-NI 90/10 Ferrules and Tube Inserts, PTFE Ferrules & Tube Adapters, Steel Fabrication and Assemblies, Spool Piping, Column Pipes & Steel Column Extension, Multistage Restriction Orifice Assembly, FLOW MEASUREMENT FLOW METERS , Dish Head Plates, Ellipsoidal Dish Head Plate, Flanged only Dish head Plate , Approximate ellipsoidal dished, Conical Head Disk Plate, Deep dished head Plate, Hemispherical Dish head Plate , Shallow dished head, ASME 80-10 Flanged Dished Head non sectioned , Shell for Pressure vessel and Tank, Tapered Tube Plug, Monolithic Insulating Joint, ASEC SLEEVE, MATERIAL, Carbon Steel Flanges, ASTM A105 Flanges, ASTM A350 Lf2 Flanges, ASTM A350 Grade LF2 Forged Flanges, ASTM A350 Grade LF3 Forged Flanges , Alloy Steel Flanges, ASTM A182 F5 Forged Flanges , ASTM A182 F9 Forged Flanges, ASTM A182 F11 Forged Flanges, ASTM A182 F22 Forged Flanges, ASTM A182 F90 Forged Flanges, ASTM A182 F91 Forged Flanges, ASTM A182/A182M – Forged and Steel Pipe Flanges., Alloy Steel Fittings, ASTM A234 Gr. WP1 , ASTM A234 Gr WP5 , ASTM A234 Gr WP9 , ASTM A234 Gr WP11, ASTM A234 Gr WP12, ASTM A234 Gr WP22, ASTM A234 Gr WP91, Carbon Steel Fittings, ASTM A234 Gr WPC, ASTM A234 Gr. WPB, ASTM A420 Gr WPL3 , ASTM A420 Gr WPL6, Carbon & Alloy Pipes , ASTM A106 Gr. B Seamless Pipes, ASTM A335 Grade P5 Seamless, ASTM A335 Grade P9 Seamless, ASTM A335 Grade P11 Seamless, ASTM A335 Grade P22 Seamless, ASTM A335 Grade P91 Seamless, ASTM A335 Grade P92 Seamless, Stainless Steel Fittings, ASTM A403 Gr WP304, ASTM A403 Gr WP316 / WP316L, ASTM A403 Gr WP347 . ASTM A403 Gr WP321, High Tensile Fittings , ASTM A860 WPHY 52 , ASTM A860 WPHY 56 , ASTM A860 WPHY 60, ASTM A860 WPHY 65, ASTM A860 WPHY 70 , ASTM A860 WPHY 80, ASTM A285 GRADE C PLATES, ASTM A283 GRADE C PLATES, High Nickel Alloys

Aditya Steel Engg. co. Manufacturer, Stock, Supply and export to :

India, Saudi Arabia, Bangladesh, United States, UAE, Canada, Angola, Argentina, Austria, Azerbaijan, Pakistan, Peru, Chile, Spain, France, United Kingdom, Indonesia, Israel, Iran, Kuwait, Mexico,Malaysia, Nigeria, Serbia, Singapore, Taiwan, Chile , Venezuela, Ecuador, Netherlands, Brazil, Colombia, Ghana, Iran, Denmark, Poland, Australia, Afghanistan, Bahrain, Costa Rica, Egypt, Iraq, Jordan, South Korea, kazakhstan, Sri Lanka, Lithuania, Norway, Oman, Philippines, Poland, Qatar, Russia, Vietnam, South Africa, Nigeria Mexico, Turkey, Hungary, Algeria, Belarus, Belgium, Bhutan, Bolivia, Bulgaria,Croatia, Czech Republic, Estonia, Finland,Greece, Italy, Japan, Libya, Romania, Thailand, Trinidad, Tobago,Tunisia, Ukraine, Yemen, Hong Kong, Gabon, China, Portugal, Switzerland, New Zealand, Sweden, Slovakia, Kenya, Lebanon, Morocco, Mongolia